-

在线留言

发送您的问题或需求,我们将尽快与您取得联系!

×

-

PIONEERS

IN DIGITISATION AND INTERCONNECTIVITY

07/27/2020

Many people see it as a revolution, but for Fronius it is simply a living reality: digitisation. As long ago as 1997, the company developed the world's first digital power source. Once inverter technology had also been introduced, this once again represented a fundamental change to the world of welding technology. Ever since that time Fronius has been a driving force behind digitisation and interconnectivity in welding technology. Fronius is regarded as the technology leader and offers a wide range of systems that allow users to work quickly, intuitively and flexibly.

TPS: INITIAL IGNITION FOR THE DIGITAL REVOLUTION

With the launch of TPS (TransPuls Synergic) in 1997, Fronius redefined the concept of welding technology. This was the first digital power source in the world, and to this day it continues to be used successfully in numerous applications. It is still seen as a benchmark for the most demanding of technological requirements, such as those presented in the automotive and component supply industries; equipment and plant construction; or in the production of rail vehicles and ships. TPS delivered reproducible welding results of a quality that had never been achievable before. Maximum output is guaranteed thanks to the system's excellent stability and the digital control of the arc. The technology on which the TPS series is based has enabled the most compact MIG/MAG pulsed arc system in the world – the TPS 2700 – to be developed. Weighing in at a mere 27 kg, this provides the user with a welding current of 270 A. A further plus point of the “digital revolution” is the simple, menu-driven operating concept that allows much shorter training time and minimises mistakes. Thanks to a variety of wizard programs, the user can work with the TPS faster and more efficiently than ever before.

TPS/I: SPOTLIGHT ON THE INTERACTION BETWEEN MAN AND MACHINE

Fifteen years after the launch of the TPS, Fronius once again revolutionised the welding technology sector with its intelligent equipment platform TPS/i. As the successor to the TPS, the MIG/MAG power source introduces additional functions for perfect weld seam quality. One of the things that makes this possible is the modular design of the welding system: this means that it is extremely easy to add on different welding processes and software options as required. The primary focus is on the interaction between man and machine. The intuitive plain-text display shows all the device parameters along with explanatory text, and the system automatically detects all available components, thereby preventing from the very outset mistakes such as using incompatible components. Another impressive feature of the TPS/i is the flexibility with which it can be used: different welding packages allow the user to work with different process variants, including PMC (Pulse Multi Control), LSC (Low Spatter Control) and CMT (Cold Metal Transfer) – all developed by Fronius. The “cold” MIG/MAG welding process of CMT is especially versatile and is suitable for joining extremely thin sheet metals as well as for root passes on pipelines. Furthermore, the user benefits from outstanding results even when joining different materials, such as steel and aluminium.

WELDCUBE: ANALYSING WELDING DATA AND IMPROVING PROCESSES

Welding produces a large volume of digitisable information: current, voltage, wire speed, arc and dynamic corrections as well as names of the job and the weld seam. It is important that all this data is monitored in order to guarantee that the welding process is completed efficiently without any problems. This is why Fronius has developed WeldCube, the documentation and data analysis system. The WeldCube manages the most important welding information and enables it to be displayed in a clear format. WeldCube also offers a wealth of functions that make it a truly versatile software tool. The actual values for each power source can be documented both globally at component level, and locally in relation to a specific machine. These values can be continuously monitored and analysed. Set values such as job data can likewise be monitored and are recorded by the system throughout the entire service life of the welding system. In combination with the new Fronius welding system platform TPS/i, it is also possible to create, edit and compare jobs centrally. All such data can be exported in a variety of different file formats or printed out directly. Intelligent statistics and filter functions allow one-off analyses to be performed. These are based purely on the user's individual requirements and can then be integrated on a customised dashboard. In each network, WeldCube allows up to 50 power sources to be combined; the results can be retrieved using a computer, tablet or smartphone. In this way WeldCube contributes to a high-quality production process, helps to sustainably improve processes and measurably reduces costs.

VIZORCONNECT: THE FIRST HELMET WITH A BRAIN

In collaboration with OPTREL, suppliers of active anti-glare products, Fronius is developing an intelligent welding helmet that significantly improves safety in the workplace. The VizorConnect is the first helmet to connect to and communicate with the power source via Bluetooth. As soon as the operator activates the arc ignition on the welding torch, the helmet is sent a signal to darken its visor. Even before the arc is actually ignited, the eye protection switches from open to closed mode. This prevents the eyes being exposed unprotected to the dazzling light of the arc as can happen for several tenths of a second with other systems. The helmet also offers an especially high standard of safety when the arc is momentarily covered by the workpiece. The VizorConnect thus helps with protecting the eyes and preventing fatigue.

WELDCONNECT: THE APP FOR TRACKING DOWN A SOLUTION

The Fronius app WeldConnect helps users to determine appropriate welding parameters. The software takes into account the TPS/i power source being used as well as the welding process, the base material, the filler metal and the shielding gas. Data can be entered either manually or by scanning the QR codes of the materials (base material, gas and welding wire) using a mobile device. WeldConnect uses this data to quickly and accurately calculate the deposition rate and (for an assumed welding speed) the energy input. It then generates a final welding solution. So there is no longer any need to access the power source or fathom out the correct parameters. The results can be stored, transferred wirelessly to the TPS/i power source in the form of a job or shared with a colleague from one smartphone to another. Users benefit from the app being so simple to use, from being guided through the sequence of operations, and thus being able to configure suitable welding solutions incredibly quickly. WeldConnect is available in German and English for Android and iOS devices.

VIRTUAL WELDUCATION: A FREE INTRODUCTION TO THE WORLD OF WELDING

How would you like to have useful facts on all aspects of welding explained on your smartphone or tablet? Or perhaps the ability to experience product information interactively? Fronius makes such things possible with its new app Virtual Welducation. This free software from Fronius combines a fun approach to the material with a gaming and quiz application, and also boasts an augmented reality application (MagicFolder) for virtual welding. MagicFolder is child's play to use and works in combination with the new Virtual Welding brochure: a coded mark in the form of a graphic is printed on every page of the brochure. If the reader wants to access any additional information they simply have to capture these coded marks using the camera on their smartphone or tablet for the app to then provide them with videos on Virtual Welding, 3D simulations of welding processes and explanations of the most important merits of virtual welder training. With the help of the quiz application, the user can gain a solid basic understanding of welding in a fun way. The game imparts initial experience of welding itself. A points system and a number of different levels serve to increase the user's motivation. The Virtual Welducation app is available free of charge for Android and iOS.

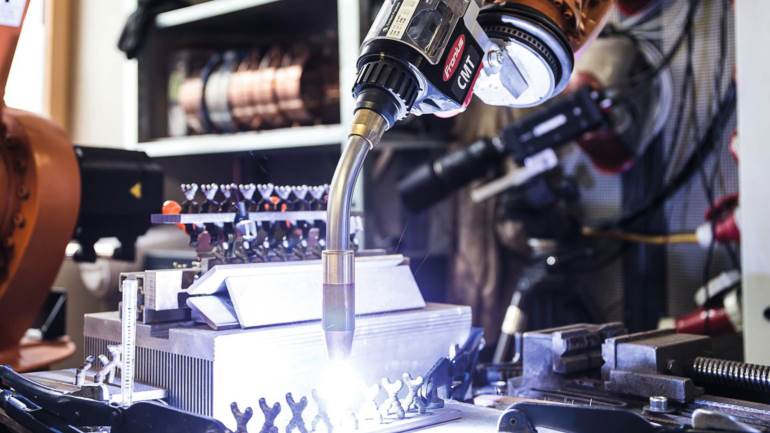

ADDITIVE MANUFACTURING: WELD COMPLEX 3D MODELS WITH EASE

Complex components that are created more or less from nothing: this is made possible by generative production methods. The term 3D printing covers a variety of add-on processes that are currently being developed, leading to interesting alternative production methods. Some of these developments apply to welding technology. There is a process known as Wire Arc Additive Manufacturing (WAAM), whereby the layers of a component are built up one after another using a welding system controlled either by a robot or CNC. This process involves the use of no additional tools whatsoever. In this way, parts with sophisticated geometries can also be produced very easily. At the SCHWEISSEN & SCHNEIDEN 2017 fair, Fronius will be demonstrating the huge potential of additive manufacturing with a 3D model of a figure produced using the WAAM method. It consists of multiple weld points, each of which is produced from a specific number of welding cycles. The process uses a robot welding system, a TPS/i power source and the CMT welding process. The Cycle Step-function enables each droplet that is deposited to be controlled individually. As a result, the welder can choose precisely how many drops of weld material they would like to deposit, or in other words how many cycles are to be performed. This is therefore an extremely accurate way of working that also increases reproducibility.

Thanks to the Cycle Step Function, every droplet that is deposited can be controlled individually. A high degree of precision and repeatability are the result.

-

下载

下载

会员中心

会员中心

收起

收起