-

在线留言

发送您的问题或需求,我们将尽快与您取得联系!

×

-

MORE EFFICIENCY IN POWER PLANT CONSTRUCTION

07/21/2020

Limited space and high quality requirements demand clever solutions so that welders can work efficiently, ergonomically, and safely. To find such a solution, you need look no further than Fronius. They advised Bilfinger Industrial Services to invest in a push-pull welding torch with a long hosepack, while a TPS/i power source ensures the perfect weld seam is achieved.

The purchase was prompted by an order for steel components for the nearby Traunleiten hydroelectric power plant, which is undergoing significant reconstruction works. The contract covered the engineering, production, delivery, and assembly of 23 different steel components weighing around 350 tons in total. These components included intake gates, turbine intake bulkhead gates, coarse screens to protect the turbines, and two weir gates, known as fish belly flap gates.

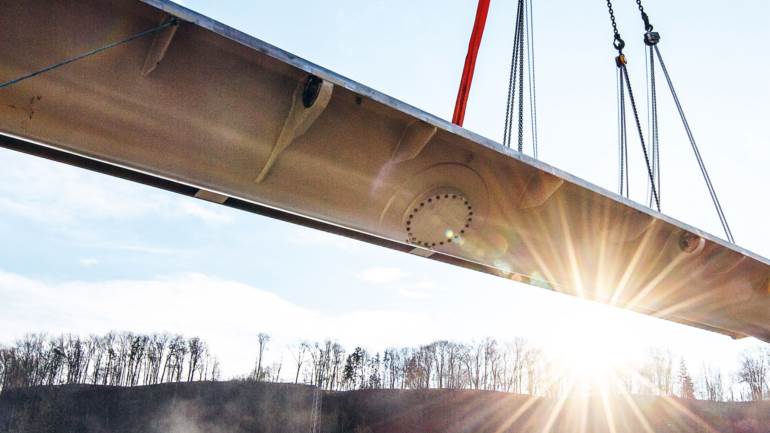

FORTY-FOUR-METER-LONG FISH BELLY FLAP GATE

In run-of-river plants, fish belly flap gates control the level of the water. They owe their name to their arched shape, which is reminiscent of a fish belly and makes them particularly torsion-resistant. For the Traunleiten project, two rotary gates, each measuring 44 meters in length, were ordered, and which are connected to the side wall of the barrage at one end by means of a hydraulic positioning drive. The approximately 2.5-meter-high gates are connected to the threshold of the barrage via a rotation axis. This allows the fish belly flap gate to be raised and lowered and thus the water level to be regulated quickly.

“Due to the transport restrictions, the gate bodies were divided into three segments of up to 16 meters each,” says Bernhard Brindl, Project Manager in the Hydro Division of Bilfinger in Wels. “The parts were joined on the construction site using flange plates with high-strength bolted connections, which requires regular checking of the tightening torque.” A resealable manhole with a diameter of 650 millimeters had to be provided for each Segment.

INDISPENSABLE MULTIPLE MANHOLES? NOT ANY MORE!

For an access point to be sufficient for maintenance, Bilfinger needed at least two manholes in order to weld together the 16-meter-long segments with the welding equipment previously available. Welders would have needed to take the power source, including the wirefeeder, into the inside of the gate segments in order to achieve all the necessary welding positions. “We would have had to subsequently weld the additional access points shut again and check their tightness. Aside from the additional costs, each additional manhole represents a weak point where water could penetrate,” Brindl explains.

» The result impressed us all. «

Bernhard Brindl, Project Manager in the Hydro Division of BILFINGER in Wels

600 METERS OF WELD SEAMS

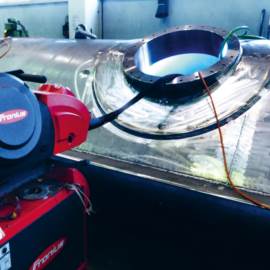

Fronius recommended that the Bilfinger experts use a long hosepack in conjunction with a push-pull welding torch and a power source from the latest generation of TPS/i devices. Bilfinger has long relied on Fronius. “We have several hundred Fronius devices, used by more than 300 welders – both in workshops and on construction sites,” adds Brindl. The industrial service provider therefore followed the recommendation and ordered an eight-meter-long PullMig welding torch as well as a TPS 500i for the construction of the torsion gates.

The experts mainly welded S355 steel plates with fillet welds andsome V butt welds with a total length of roughly 600 meters. They started with the construction of a steel tray that forms one side of the gate, onto which struts and then the “lid” were welded. The welders had to adhere to tight tolerances in the millimeter range and observe minimum welding distortion so that the parts could subsequently be bolted together precisely and mounted on the rotation axis. In order to largely avoid out-of-position welding, the welders repositioned the gate several times with a roller crane.

MORE FREEDOM OF MOVEMENT

“The result impressed us all,” says Brindl. “The extended operating radius due to the long hosepack allowed us to dispense with the second manhole for each segment, saving us the additional work this involved.” In addition, the welders were able to place the power source together with the wirefeeder outside the gate body and still attain all the required positions. “This not only gives us better freedom of movement in the already restricted space with a cross-section of just 1,500 by 800 millimeters, but also facilitates – and this is crucial for us – access and recovery for emergency rescue workers.”

The equipment offers a number of other advantages, which also have a direct impact on efficiency, ergonomics, and quality in pipeline, container, and ship construction. All the important welding parameters can be set via the JobMaster remote control, which can be called up directly on the torch body. This allows the welder to perform different welding tasks straightaway without additional work and long interruptions. “Our welders rated the steady wire speed particularly highly,” reports Brindl. In addition, an LED light integrated in the welding torch makes it easier to work in poorly lit areas. Yet the welding torch is extremely compact and weighs only 1.6 kilograms, despite the integrated two-roller drive, making it one of the lightest in its class. Together with the rapid control of the arc and the stabilizing PMC pulse process that are typical for the TPS/i devices, the highest quality requirements can be met efficiently, safely, and conveniently.

LASTING SUCCESS

“The welders would prefer to only work with this device,” summarizes the Project Manager. “We immediately reserved the TPS 500i with the long PullMig welding torch for our department. The container construction department followed suit and also ordered a long hosepack. This allows the welders to devote themselves entirely to the task at hand and benefit from the increased operating radius, even with larger containers.”

-

下载

下载

会员中心

会员中心

收起

收起