-

在线留言

发送您的问题或需求,我们将尽快与您取得联系!

×

-

CONSISTENT QUALITY, SPOT AFTER SPOT

RESISTANCE SPOT WELDING

07/27/2020

At the end of the 19th century, copper electrodes began to be used for resistance spot welding for the first time. It did not take long for this joining process to make its big industrial breakthrough. In the 1930s, the process started to become widely used in vehicle manufacturing and has since become indispensable.

The welding process is simple, energy efficient, and does not require any shielding gases or filler metals. It is hardly surprising that it is one of the most cost-effective joining processes in the world. Resistance spot welding uses a current, which is transferred to the workpiece via a highly conductive electrode with a low thermal resistance. The force generated is applied to the workpiece: the plates being joined heat up at the contact points until the desired weld diameter is achieved – causing the workpieces to fuse together.

WHAT ARE THE APPLICATIONS OF RESISTANCE SPOT WELDING?

Around 80 percent of the time, resistance spot welding is used for standard steel applications. The notable trend towards lightweight construction – lower mass leads to lower energy consumption and lower CO2 emissions – means that the demands being placed on joining technology are increasing. This trend also means that the automotive industry, which makes up around 85 percent of the global resistance spot welding market, is using an increasing amount of aluminum. Welding aluminum is a significant challenge and the weld properties differ considerably from those of steel. While steel melts at around 1,500 degrees Celsius, the oxide layer that coats aluminum only melts at around 2,000 degrees Celsius. Aluminum itself actually melts at around 650 degrees Celsius. Resistance spot welding is also used in the railroad, aerospace, and aviation sectors. Fronius has a range of different resistance spot welding systems in its portfolio: DeltaSpot with a strip electrode and DeltaCon, a conventional spot welding system.

THE ADVANTAGES AT A GLANCE

Where special surface criteria, low spatter, and cost-effective joints are required, resistance spot welding systems from Fronius are the perfect solution. The DeltaSpot spot welding system with a continuous process tape is unique global innovation that guarantees consistent quality with every spot. This is particularly important for the automotive industry, as a car usually has somewhere between 4,000 and 5,500 welding spots. With DeltaSpot, it is possible to produce between 4,000 and 7,000 spots without any interruption and at a consistent surface quality. Furthermore, the process tape protects the electrode from pick-up, wear, and contamination. This saves the user a lot of time and reworking. Conventional guns tend to experience electrode sliding, resulting in a loss of quality. The high rigidity of the DeltaCon counteracts this, and electrode sliding is restricted to less than 0.85 millimeters. Owing to this rigidity and the advanced Fronius welding controller, it is possible to extend the service life of the electrodes while consistently maintaining outstanding levels of quality.

High productivity with low costs is a decisive argument for resistance spot welding. It is not without reason that the welding process is the most commonly used technique for joining thin sheets on the market. The main driver of this is the automotive industry. As well as the more well-known sectors, Fronius has discovered new industries that also benefit from this proven joining process – such as the manufacture of energy distribution systems and elevators. As a result, theapplication areas for resistance spot welding will certainly continue to grow.

» The best thing about spot welding systems from Fronius? The customer can get the entire system, from the gun to the controller, from a single supplier. We understand the process, the mechanics, and the electronics. This makes life simpler for the customer – instead of having to source products from different gun and control system suppliers, they can get the whole package from us. «

Gerald Schmitt, Head of Product Management Resistance Spot Welding

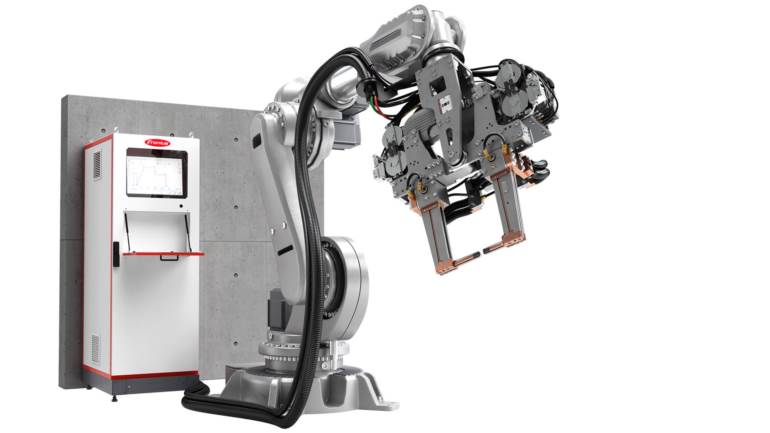

DELTACON

The gun for conventional spot welding was specially developed to be used with aluminum. In comparison to steel, aluminum has a lower level resistance, which means higher forces and amperages are required to join the materials. Due to the high degree of automation, the system is suitable for every production line.

DELTASPOT

The spot welding system with continuous process tape is a unique global innovation and perfectly suited to joining steel and aluminum, as well as thin sheets and multiple sheets. The system is ideal for workpieces that require a high number of welding spots, as the DeltaSpot can weld up to 7,000 spots without interruption. This has a particularly positive effect on the cycle time.

-

下载

下载

会员中心

会员中心

收起

收起